The following process allows you to use ECMSpy to rest the Throttle Position Sensor (TPS) on pre-08 Buells - see bottom of the page for 08 and later Buells.

Note

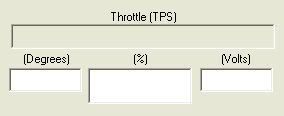

This process tells the ECM what the TPS output voltage is when the throttle butterfly is fully closed.Throttle position and Throttle (%) are positions relative to the zero point for the throttle butterfly. The purpose of a TPS reset is to tell the ECM what voltage is at the pot when the butterfly is completely closed (i.e., 0% open). The ECM is then capable of calculating the exact throttle position based on the offset voltage from the absolute voltage reading that it read when the butterfly was fully closed. Throttle position is the measure of the angle (degrees) that the throttle butterfly open between 0 and 85.

Note

The TPS output Voltage at condition can change over time as the result of system wear or sensor movement.Note

A TPS reset is part of the 1000 mile, 10,000 mile and 20,000 mile (and 10,000 miles thereafter) services.Note

This process works on all Buell ECMs.This process is shown for use with the PC version of the ECMSpy tool.

WarningTo prevent ECM EEPROM corruption, this operation should only be performed with a fully charged battery and ideally with the “Lights” fuse removed.

WarningECMSpy is a powerful tool. In inexperienced hands, it can result in your ECM being rendered useless.

Using ECMSpy for PC (V1.12.1)

1. Turn on PC

2. Load ECMSpy

3. Connect your PC to the Data Link Connector using the ECMSpy USB lead

Note

Data Link Connector can be found:

XB R - under LH side lower fairing spar

XB S/SS/SX/STT - Under seat to right of the ECM

XB X/XT - LH opening of the seat subframe (no need to remove the seat - although it is easier to do so)

X1/S3 - RH side of the headstock up to MY 2000. Under the seat, LH subframe rail on MY 20014. Turn on the ignition and ensure the engine kill switch is set to run.

5. Click on, and “depress” the Online/Offline button.

Note

Note

This allows ECM data to be displayed in real time.6. Locate the idle adjuster (also known as the throttle stop screw).

Note

The idle adjuster location:

XB - Inboard of the left hand airscoop on an XB

X1 / S3 - LH side of the bike, in between the cylinder heads, cable tied to the bridging bracket that the upper tie bar bolts to. Recommended that the LH plastics are removed for easier access7. Using a 3/16 allen key, and whilst watching the TPS Voltage unscrew the idle adjuster until the Voltage no longer reduces.

8. Unscrew the idle adjuster a further full turn.

9. Open the throttle and snap it shut three times.

Note

This ensures the throttle butterfly is fully closed.Note

The easiest way to check if the throttle stop is no longer engaged is to turn the throttle grip to zero and force it there gently. If when you start to open it, you can feel it gently sticking, this means that the butterfly is wedging in the throttle body and you have achieved absolute closureNote

When forcing the throttle closed so that it gently sticks as described above, note the TPS Voltage value each time. It should be within .01 volts each time you do this. If not, there is something wrong with the throttle body or Throttle Position Sensor.Note

Before you actually reset your TPS to zero, It is recommended a test of the TPS reset procedure is performed in order to confirm that the TPS reset is working properly. This is optional but may save some headaches if things don’t seem to be working right later. Hold the throttle in the 1/3 open position, and then execute a TPS reset with it held steady there. Close the throttle and go back to Overview mode. Slowly open the throttle. If the Throttle Position bar graph remains stationary until you cross the threshold position that you held the throttle at (i.e., 1/3 throttle) and only then starts climbing, THEN you know that ECMSpy is communicating correctly and that you have successfully set the TPS10. Whilst watching the TPS Voltage, open the throttle slowly. If, after taking up the slack in the cables, the Voltage fails to start to increase immediately, there is the possibility that the TPS sensor is not correctly installed, this operation should be terminated and the instructions in section * followed.

11. Click on the Diagnostics tab.

12. Click on the Reset TPS button.

13. Click on the Overview tab.

14. Ensure the Online/Offline button is “depressed” and “depress” if necessary.

15. Whilst monitoring the TPS degrees, screw the idle adjuster until reaching a value of 5.2 to 5.6 degrees.

16. Save the EEPROM as a record of the current status of the ECM.

17. Turn on the ignition, start the engine and run until the engine temperature reaches 160 degrees C.

18. Using the idle adjuster, set the idle speed between 1050-1150 RPM.

19. Turn off ignition, replace fuse if necessary.

20. Disconnect ECMSpy cable from Data Link Connector and replace rubber cover.

08 and later BuellsThe 08 and later have a completely different procedure and doesn’t need ECMSpy.

Turn the ignition on, engine kill switch to run, twist the throttle 3 times - keep the throttle fully open for one second and fully closed for one second.

Job done!