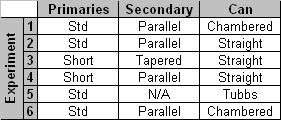

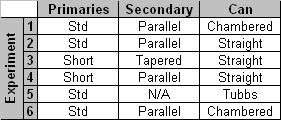

Thought it was about time we wrote up the experiments carried out with tubbs at Moorespeed Racing.

I accompanied Albert666 and wkd1 to test of a number of exhaust designs. These have been listed as experiments below:

The dimensions of these pipes are Albert's property, and lets face it, even if you did have the dimensions, you would would be stretched to better the quality of Albert's work.

Firstly, we are always wiser after the event, so a few things we would do better next time...

Experiment 1 was run with no ignition pick up cos we didn't want to take too much of Colin Moorespeed's time. Not a big deal if you are looking for a hard power figure, however, the 1125 makes good power up to the rev limiter, and if you don't run the engine to the rev limiter each time, you are going to miss the peak. And if you miss the peak and you want to compare performance to other tests, what do you have to fall back on? The torque... But if you don't have an ignition pickup, you do not have ready access to engine speed, which you need for torque calcs. Perhaps the dyno had a screen where a conversion could be added, but I didn't know about it. In addition, the Dyno Loop was not obvious like on an XB so we didn't know how long it was going to take us to rig up... Sure you could do some post processing with Excel, but that doesn't give the easy access to data that the Dynojet system gives you. Experiments 1 and 2 were run with no WB lambda sensors.

So, if we could do it again, we would have

1. Fitted the current probe on the ignition at the start

2. Fitted the lambda sensors at the start

3. Taken the bike up to the rev limiter each run

Secondly, there are differences in dynos as well as test mules, so the results from this dyno may not be comparable to the results from one in Mongolia, likewise the bike we used to test with may not perform the same as another.

The important thing is that we used the dyno as a tool to determine the differences in performance between pipes.

To make it as fair as possible, we did at least 3 runs for each pipe and picked the best run, based on the torque curve, to represent that configuration, i.e. we were not *sympathetic* to a particular product...

So, based on the above, in my eyes, experiment 2 gave the best performance, but there is not a lot in it...

Looking at the AFR, or rather lambda, we can see that all experiments have similar characteristics, which is not surprising as they all have a similar torque curve.

I was impressed how repeatable these were for different coolant and inlet air temperatures, shows someone has the corrections right, although you could argue that the changes are very small...

But what can we do with this data, what does it mean?

Well:

1. If you change your exhaust to an Albert or a Tubbs, it isn't going to run lean at high power

2. With this data we can remap by studying the deviation from lambda=0.9, and applying that factor to the fuel maps in TunerPro.

How much power can we gain? Probably not much more than 5%. We will gain power where lambda is leaner than 0.9 (i.e. above 0.9) but we are unlikely to gain power where lambda is a little richer than 0.9 (i.e. around 8.5), but we will reduce the amount of fuel used, which on a race bike may save weight, or a fuel stop depending on how long the race is.

So, what did we learn? From what we tested, and we tested a few different designs, the results show that the 1125 is generally insensitive to exhaust changes. Sure, Tubbs has shown that you can get a 6% increase in power over stock by gutting the pipe whilst maintaining an acceptable noise level, but we did not have a stock exhaust to test (and they go rusty), and we did test against Tubbs' pipe, so we have a known baseline.

We also learned that the fuelling is not really that bad with any of these pipe designs, which supports the comment that the engine is insensitive to exhaust design. Sure, you could probably get another 5% along the torque curve, and this is something we can look into another day.

And linked to the above, you can see that anyone telling you your bike is running lean (bear in mind we tested a BUZD ECM) with a new exhaust, and that you need to pay them money for a remap for safety's sake is stringing you along...

Finally, Tubbs' exhaust was the quietest, but I will leave someone else to talk about that.

Something else which may be worth exploring, is to raise the rev limiter, sure we are talking potential engine damage, but the motor does want to rev a bit more...

Big thanks to Colin and Tubbs at Moorespeed for support through the day of testing...